我的商店

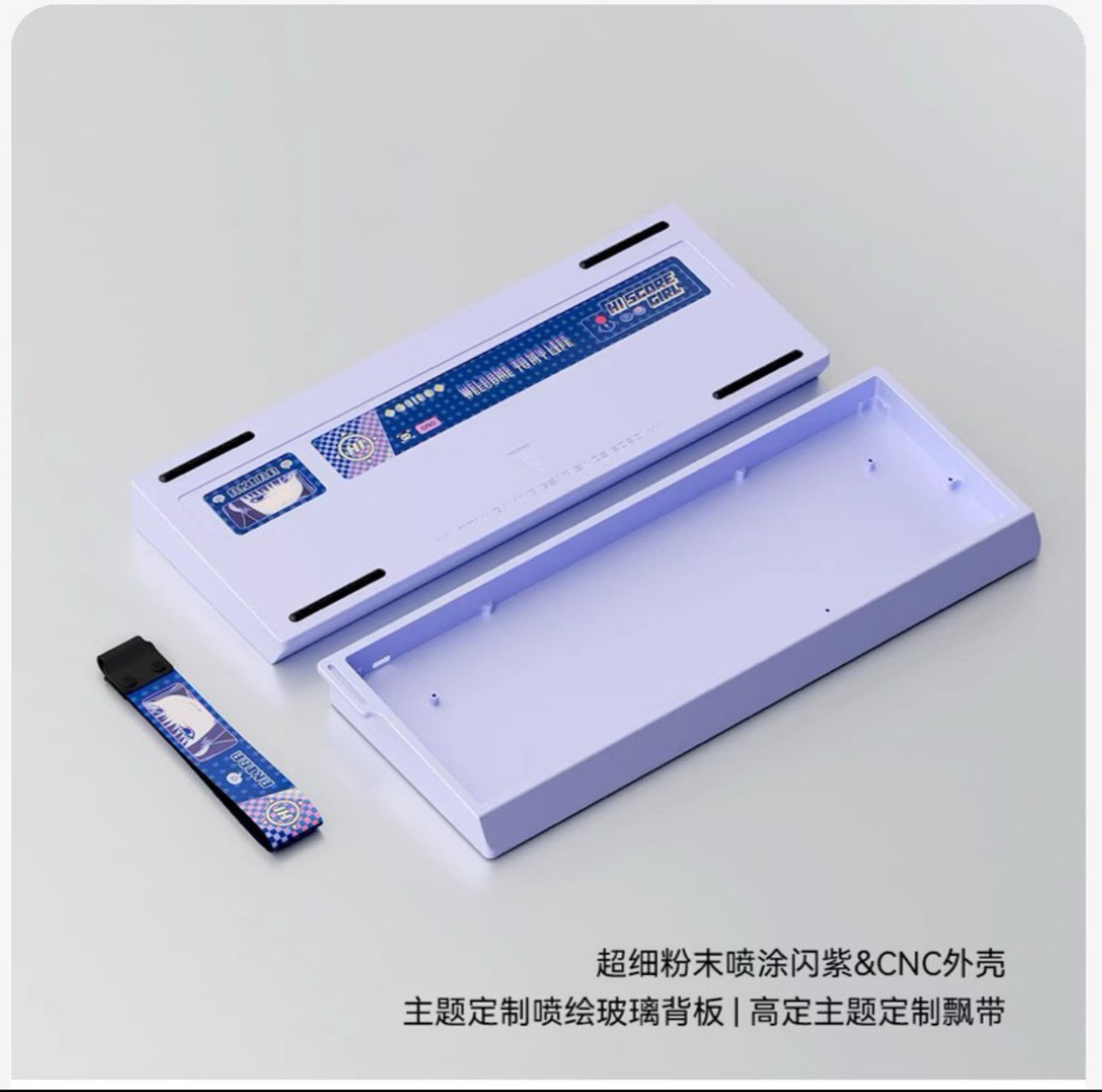

TITAN60 Keyboard Aluminum Case

TITAN60 Keyboard Aluminum Case

无法加载取货服务可用情况

Process

220 mesh sand blasting anode

Ultra-fine powder coating

Electrophoresis

Shell material

National standard 6063 electronic aluminum

Filling

4MM EPDM high density bottom sound deadening cotton

Structure

Tray Mount stable and durable hull structure

Bottom Decoration

Skyglide customized airbrushed glass backsplash with high end theme

Accessories

Screws x 8 Screwdriver x 1 Customized strap x 1

Packaging

“Monochrome Silver” Gift Box Keyboard Package

Appearance surface QC standard:

-Front surface (top view) defects (pits, trachoma, air holes, bumps, etc.) do not exceed 1MM and not more than three in the same plane. Side and bottom surface allows 4-6 defects <0.9MM in diameter and <5CM in distance;

-30CM distance from the appearance of the surface without obvious processing knife lines, no scratches and bumps. The appearance of the surface allows the chamfer of the workpiece, the joints have a small joint knife lines

-Glass mirror surface shall not appear more than 1MM white spots / pits; embedded with the bottom shell there is a small tolerance, the four sides of the gap has a slight unevenness is a normal phenomenon gap is not included in the QC standard.

-Normal angle inspection shall prevail, specific angle, specific light inspection is not recognized.

Internal QC standard:

Due to the mass production of customized products and large shipments, it is not possible to make internal QC standards, normal knife lines, chamfering hanging point corner bumps, are normal phenomena. Our requirement for factories is the same standard inside and outside, but due to the impossibility of QC one by one, the internal surface is not included in the scope of QC after-sales service for the time being.

Share